Chii chinonzi Induction Hardening?

Chii chinonzi Induction Hardening?

Induction kuomesa inzira yekudzima iyo inoshandisa musimboti we electromagnetic induction kuita kuti workpiece iteme magineti mitsara mune inochinjika magineti uye kugadzira induced ikozvino pane simbi zvikamu 'pamusoro. Zvinoenderana nemhedzisiro yeganda rekuchinjisa ikozvino, pamusoro pechikamu chinopisa chinokurumidza kupisa muchimiro cheiyo eddy ikozvino uye ipapo induction inodzima nekukurumidza.

mushure induction kupisa muchina inopedza kupisa uye kudzima maitiro, zvikamu zvesimbi pamusoro pekuoma kwakakwira, iyo musimboti inochengetedza yakanaka plastiki uye kuomarara, ichiratidza yakaderera notch senitivity, saka kuoma kwemhedzisiro, kuneta simba, uye kupfeka kuramba kunovandudzwa zvakanyanya. Nekuda kwenguva pfupi yekudziya, iyo oxidation yepasi, uye decarburization yezvikamu zvishoma, zvichienzaniswa nemamwe marapirwo ekupisa, chiyero chekuramba chikamu chakaderera kwazvo. Zvakare kusarudza iyo yakakodzera induction yekudziya coil inoita basa rakakosha mumunda wesimbi induction kupisa kurapwa.

Sei uchishandisa induction kuomesa maitiro?

Induction quenching inzira iyo eddy currents inogadzirwa musimbi workpiece ne electromagnetic induction uye workpiece inopisa. Kuenzaniswa neyakajairwa simbi yekudziya tekinoroji, induction quenching tekinoroji ine zvinotevera zvakanakira:

1. The metal workpiece pamusoro kuoma kwakakwirira. Iko kuomarara kwepamusoro kwechishandiso chakaomeswa nepamusoro uye yepakati frequency induction kudziyisa ndeye 2 ~ 3 HRC yakakwira kupfuura iyo yakajairwa kudzimwa. Yayo simbi inokanganisa kuoma, kuneta simba, uye kupfeka kuramba inovandudzwa zvakanyanya. Hupenyu hwesevhisi yesimbi workpiece inogona kuwedzerwa zvakanyanya nekudzimisa induction.

2. Iyo simbi workpiece haina kusanganisa kudziyisa, saka nekuomesa induction, iyo workpiece yakazara deformation idiki;

3. Iyo simbi workpiece yekudziya nguva ipfupi, iyo yepamusoro oxidation decarburization huwandu ishoma;

4. Heating sosi inoshanda musimbi workpiece pamusoro, kupisa kumhanya uye kunyatsoshanda kwakakwira;

5. Induction quenching equipment chimiro chakanyanya compact pane yakajairika simbi induction yekudziya michina, iri nyore kushanda.

6. Induction kuomesa muchina unoona mechanized uye otomatiki kupisa kurapwa kugadzirisa, kuchengetedza mutengo wevashandi.

7. Induction kuomesa tekinoroji mukuomesa kwepamusoro inogona kushandiswawo mukupisa kwekupinda uye kurapwa kwemakemikari kupisa.

Nzira yekusarudza sei yakakodzera induction Kuomesa maitiro?

Iyo induction kuomesa maitiro ane akati wandei ekudziya nzira uye ese ane akakodzera ekudziya ekushanda.

1. Imwe-nguva induction yekudziya yekuomesa nzira:

Imwe-nguva induction kudziyisa kana panguva imwe chete induction kudziyisa ndiyo yakajairika induction kuomesa nzira. Kana iyi nzira ichishandisa machubhu maviri ane rectangular akatenderedza nzvimbo yekushanda yekudziya inotenderera, inowanzonzi Single Shot.

Chakanakira iyi induction yekudziya nzira ndeyekupedzisa ese workpiece pamusoro penzvimbo induction kupisa mabasa panguva. Nokudaro, kushanda kwayo kuri nyore, kubereka kwakakwirira, kwakakodzera kupisa nzvimbo ye workpiece haisi yakakura. Kuti udziye iyo yakakura nzvimbo workpiece, tora iyo imwe-nguva yekudziya nzira, inoda simba rakakura uye yakakwirira mari yekudyara.

Mienzaniso yakajairika yeimwe-nguva induction yekudziya kuomesa magiya madiki uye epakati modulus magiya, CVJ bhero-yakaita mabhomba mabara, mukati mijaho, mavhiri anotakura, mavhiri ekutsigira, mashizha echitubu mapini, anodhonza, mavharuvhu anopera, valve rocker arm arcs, nezvimwe.

2. Kuongorora induction kuomesa nzira:

Kana iyo workpiece yekupisa nzvimbo yakakura, iyo induction yekupisa magetsi ishoma, nzira iyi inowanzoshandiswa. Panguva ino, iyo yakaverengerwa yekudziya nzvimbo S inoreva dunhu rine mhete yekupinza. Naizvozvo, iyo yakafanana simba density, iyo induction kupisa muchina chinodiwa simba idiki, the makwikwi induction hardening machine mutengo wekudyara wakaderera, wakakodzera diki batch induction kuomesa kugadzirwa, yakajairwa mienzaniso yakakura-dhayamita piston tsvimbo, corrugated roll, roll, pombi yemafuta, sucker tsvimbo, njanji, muchina chishandiso chinotungamira njanji uye zvichingodaro.

3. Subsection imwe-nguva induction kudziyisa quenching nzira

Mienzaniso yakajairika ndiyo yakawanda camshafts induction kuomesa, pese painopisa imwe kana akawanda cams, mushure mekupedza nguva ino induction kudzima, kupisa imwe cam chikamu, magiya akaomeswa zino nezino anogona zvakare kuverengerwa muchikamu ichi.

4. Subsection induction scanning yekudzima nzira

Mienzaniso yakajairika mavharuvhu e rocker shafts kana kuchinjika kumhanya shafts induction kuomesa, uko akawanda mashefu eshaft akaongororwa kuti adzime induction, upamhi hwekudzima hunogona kunge hwakasiyana, uye kudzima zino nemeno kunogona kuverengerwa muchikamu ichi.

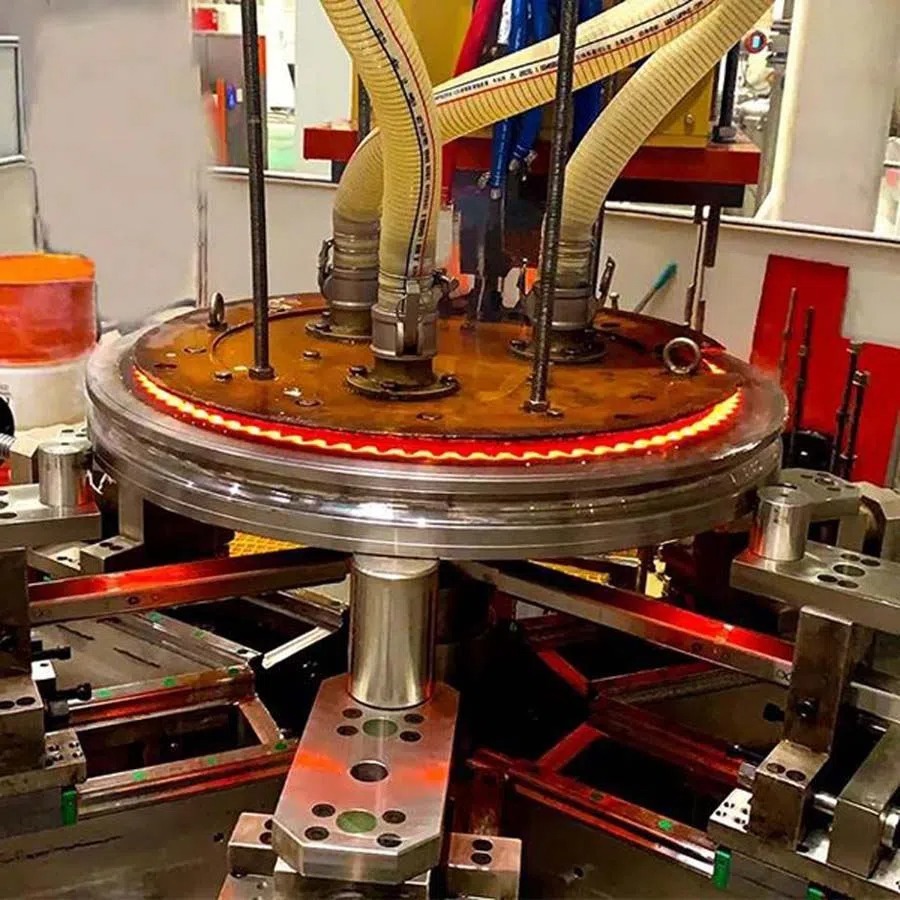

5. Induction kupisa uye kudzima mumvura

Induction kuomesa kudzima mumvura, zvinoreva iyo induction coil uye workpiece kudziyisa pamusoro anonyudzwa mu induction quenching mvura, inopisa, nokuda kudziyisa pamusoro pesimba simba density kuva yakakura kupfuura akapoteredzwa quench fluid kutonhora mwero. Nokudaro, nzvimbo yacho inopisa nokukurumidza. Kana iyo inductor ichidzimwa, iyo pamusoro peiyo workpiece inoomeswa nekuda kwekupisa kwekupisa kweiyo workpiece core uye kutonhora kwemvura inodzima.

Iyi nzira inowanzoenderana nesimbi workpiece inoda kutonhora kusinganyanyi kukosha. Kana iyo workpiece yakaiswa mumhepo uye induction coil inobviswa, kupisa kwepamusoro kunobatwa nepakati peiyo workpiece. Kana kutonhora kwemhepo kunopisa kunopfuura kutonhora kwakanyanya, workpiece yakaoma, iyo yakafanana nekudzima mumvura.

Ndezvipi zvikamu zve induction harding system?

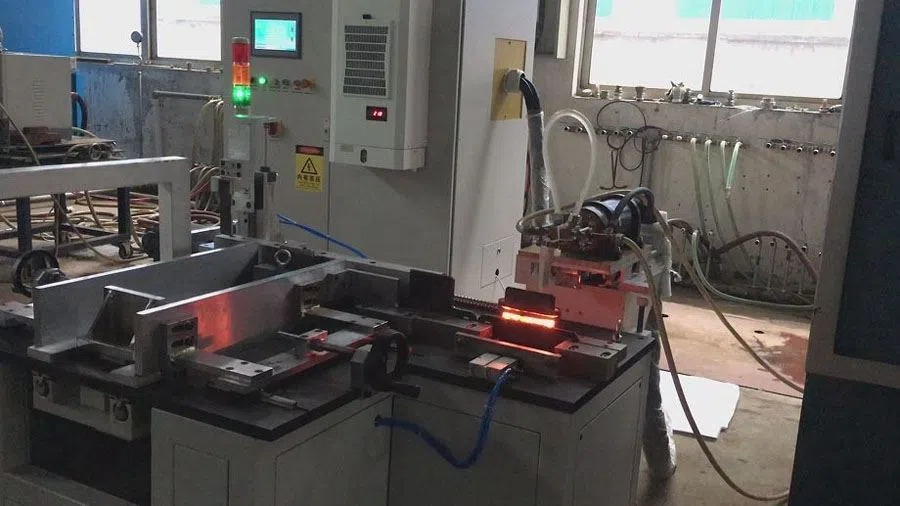

Kuumbwa kwekukwana induction kudzima muchina kazhinji inosanganisira induction yekudziya magetsi, CNC induction kuomesa muchina chishandiso, induction kuomesa coil, uye yekubatsira inotonhorera yekutenderera yemvura sisitimu uye kudzima mvura inotenderera system.

Vagadziri vemazuva ano induction yemidziyo yekudziya, chikamu chakakura chekugona kuita maseti akazara emidziyo yekuomesera uye turnkey purojekiti, mushandisi kubva pakupfupisa kutenderera kwekugadzira, uye kudziviswa nekuda kwedhipatimendi rekupa rakawanda mukugadzirisa dambudziko hariwirirane, uye matambudziko akareba ekugadzirisa senge nguva. Kupihwa kwemidziyo yakakwana uye mapurojekiti eturnkey yave nzira yekukwikwidza yevagadziri vemidziyo.

Pakazara, seimwe yevanotungamira induction kuomesa system vagadziri muChina, takabatsira zviuru zvemafekitori ekurapa kupisa kuti awane akakodzera induction kupisa kupisa mhinduro kare, saka kuitira kuve nechokwadi chakakodzera induction kuomesa system induction quenching process. Iwe unogona ndapota nditendere kuti ndive neakaomesera zvikamu zvekudhirowa, zvinhu, kuomarara, uye kuomesa zvikumbiro zvakadzika, uye isu tinogona kukupa inoenderana induction yekudziya yekuomesa system yekuomesa mazano ehunyanzvi pamwe nemakotesheni mapepa. Ndatenda.

Induction Kuomesera Kudzima System Chikamu Chekushandisa Makesi

1. Yakatendeseka yakatwasuka mujaho CNC induction quenching machine system

2. Chain Plate Induction Hardening System

3. Cantilever gear CNC induction kuomesa muchina system

4. Wind Power Bolt Induction Quenching uye Tempering System Production Line

5. Balanced shaft goko remukati gomba induction kudziyisa kuomesa hurongwa

6. Yakakura Mill Roller Induction Hardening